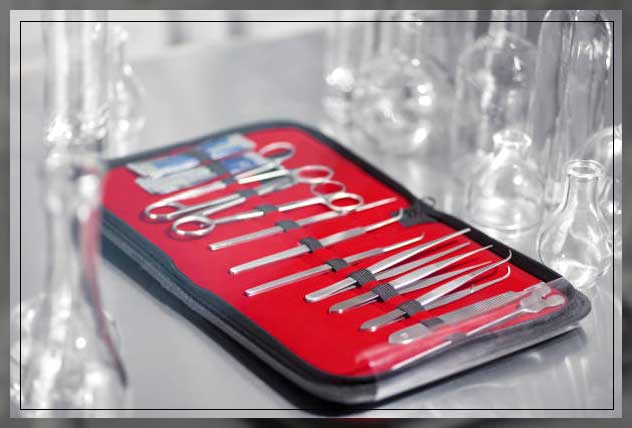

Do you know that in order to prevent infection and diseases you need to use a surgical tool sterilizer?

A surgical tool sterilizer is a device that helps to disinfect the surgical tools that you will use in a medical center or healthcare institute.

It is important to note that sterilizing equipment is a crucial element of modern medical care.

This is because patients come in contact with surgical tools, syringes, and bandages all the time while receiving treatment.

Moreover, to make sure the safety of your patients, medical practitioners, and the environment, you need to use a surgical tool sterilizer.

With thorough and effective cleaning, you can avoid the possibility of disease spreading from patient to patient.

Keep on reading to learn more about surgical tool sterilizers.

Benefits of using Surgical Tool Sterilizers

With invasive procedures, there is a contract between the mucous membrane of the patients and the sterile tissue, as well as, surgical instruments or medical devices.

Moreover, with this, there is a significant risk of these types of procedures introducing pathogenic microbes.

These can potentially result in infection.

When you do not properly disinfect or sterilize medical equipment, it can increase the risk of infection due to the breach of host barriers.

In order to protect both your patients and staff, you need to take steps to destroy germs and reduce the spread of infections.

One such example of this is fighting off against healthcare-associated infections, i.e. HAIs.

These are infections hospital patients can get due to their stay at the hospital.

Moreover, surgical instruments, contaminated equipment, or improper staff hygiene can also lead to HAIs.

Some of the major benefits of surgical tool sterilizers are as follows:

- helps to decrease the pathogenic load, i.e. the number of non-sterilized bacteria living on the surface of surgical tooths

- prevents the corrosion of expensive and highly precise tools that have intricate functional pieces

- removes the breeding ground for the surviving germs

- makes sure the safe transport of equipment that needs to be packed and assembled for sterilization or disinfection

Furthermore, with proper sterilization and disinfection, you can safely use the tools for non-invasive and invasive medical devices.

Methods of Sterilization

Some methods of sterilizing surgical tools are as follows:

Steam Sterilization

In most departments of healthcare facilities, steam sterilizers or autoclaves are present.

This is because steam can help clean many common medical devices and is the safest and cheapest option.

Moreover, some technicians also consider using another method when the medical device is made of heat-sensitive material.

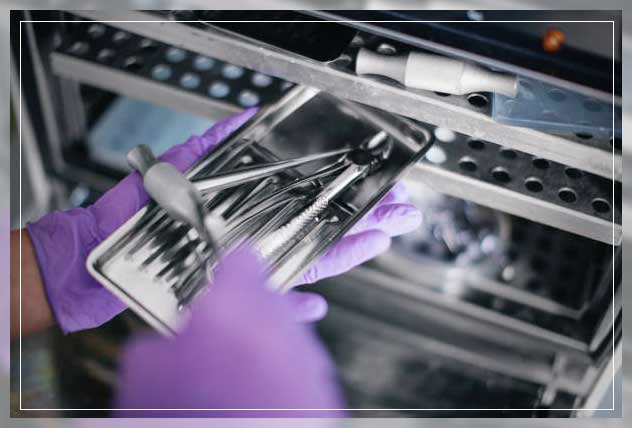

The autoclaves apply intense pressure and heat. Both of these helps to destroy all microorganism on the surgical tools.

With steam sterilizations, you can clean the outside surfaces of the medical equipment for appropriate decontaminants.

Furthermore, you can also prevent damage by using either paper or cotton to wrap the instruments before the process begins.

When placing the tools in the machine, make sure to leave enough space.

Dry Heat Sterilization

When steam is unable to penetrate an instrument or in case it causes damage, you can use dry heat.

Dry heat is a strong, however, slow technique that requires high temperatures and cycle time.

Because of this, it is not suitable for a number of tools.

However, it is often more reliable than various other options.

Moreover, it is important to note that dry heat sterilization uses air of around 340 degrees F to kill microbial life.

Other Methods of Sterilizations

Some other sterilization methods are:

Chemical Sterilization

With the help of prepared liquid chemical solutions that are involved in this process, you can sterilize medical equipment.

Ozone, ethylene oxide, hydrogen peroxide, and bleach are some of the chemicals you can use.

Moreover, these chemicals have the power to kill a wide range of pathogens and have properties that can be potentially harmful to your patients.

For this process, you need to submerge the tools into the chemical completely for a certain amount of time.

Once sterilized, rinse off your equipment and tools and allow it to try.

Plasma Gas Sterilizers

This type of sterilization uses low-temperature hydrogen peroxide-based gas plasma inside a chamber to kill any microorganisms.

You can use this process on both dental and medical equipment, including spores, bacteria, fungi, and viruses.

When you add vaporized hydrogen peroxide, it helps to sterilize the enclosed equipment.

Once you remove the vapor from the chamber, it produces a plasma of low temperature sterilizations.

This helps to makes sure total sterilization of all equipment.

The remainders of this process are oxygen and water and it makes them safe for both the environment and medical staff.

However, it is a costly method but is extremely effective and an excellent option for tools that are moisture sensitive.

Vaporized Hydrogen Peroxide, VHP Sterilizers

Just like plasma sterilization, you can use hydrogen peroxide vapors with VHP sterilizers.

However, you do not use plasma gas within the sterilization process.

With the help of VHP sterilization, it helps to remove humidity from within an enclosure and a generator rapidly injects VHP to reach an ideal concentration for sterilizing equipment.

This process helps to remove microorganisms effectively with vapors.

Now, let’s discuss different types of autoclave machines.

Different Types of Autoclave Machines Categorized

There are a number of different aspects that you can use as a basis for the categorization of the different types of autoclaves.

And some of these aspects may also overlap with each other.

In most cases, you can differentiate steam sterilizers or bowie dick test by:

- function

- class

- size or capacity

Types of Autoclaves by Function

All autoclaves use high-temperature and high-pressure steam to sterilize medical equipment and waste.

Their function indicates how you should load them and how they force the steam in their chamber to sterilize the instruments inside.

Vertical Autoclaves

You can load these types of autoclaves by opening their top lid.

These are suitable for laboratory uses or in smaller clinics with cramped spaces.

Moreover, they also have a smaller capacity chamber.

Horizontal Autoclaves

Front-loading steam sterilizers with a large capacity chamber, and when available space is not an issue, you can use them.

Also, these are exceptional for reducing the strain on your medical staff.

Gravity Displacement Autoclaveves

One of the most common types of autoclaves.

These relive on using dense steam to force out the air from the chamber of the machine.

Additionally, they are suitable for the treatment of basic loads like flat surgical tools and certain types of biohazardous wastes.

However, are not as versatile as pre-vacuum autoclaves.

Pre-vacuum or Prevac Autoclaves

These use a vacuum pump to remove all the air from the chamber of the autoclave.

It allows for better steam penetration and the sterilization of more materials and complex loads.

For example medical textile products, porous loads, large pieces of equipment, and oven objects made from high-density polyethylene-like syringes.

Types of Autoclaves by Class

This is a more clear-cut way of categorizing the different types of autoclave machines.

A class of steam sterilizers indicates how versatile it is.

In other words, it shows what kind of loads you can treat it with.

Class N Autoclaves

These are essentially simple, gravity displacement autoclaves that help to remove only a certain portion of the air inside the chamber of the machine.

Moreover, these help for the treatment of simpler loads like flat medical tools.

Class S Autoclaves

Another type of gravity displacement autoclaves that uses a wall of dense steam.

However, by repeating the process 3 times, it can actually extract all the air from the chamber.

And as such, it can treat bagged instruments and porous loads.

However, it is still less versatile and not as flat as a class B autoclave.

Class B Autoclaves

Premium pre-vacuum autoclaves can help to sterilize most materials and are also much faster at doing so.

It does so by removing all the air from the chamber with a powerful vacuum pump.

Moreover, some models also make the best out of modern technology and operate with a completely automated process.

With this, it helps with the ease of use and effectiveness making them very attractive for all kinds of healthcare and medical facilities.

Different Types of Autoclaves by Size or Capacity

This characterization is pretty straightforward.

Hover, it certainly does not make it less important to consider.

One of the key factors you need to take into account is the autoclave size.

Moreover, the right choice depends on the amount of waste your facility needs to treat each day, as well as the amount of available space.

Large Steam Sterilizers

The capacity of these types of autoclaves often ranges between 110 to 880 liters.

These are ideal for large medical facilities like hospitals that generate a notable amount of waste each day.

And for those that need to use a lot of surgical tools and equipment to treat patients.

Medium-Sized Steam Sterilizers

The capacity of these autoclaves ranges between 75 to 200 liters.

It is an excellent choice for both dental and other clinics’ biotechnological applications.

Or for operating theaters in hospitals.

Small or Benchtop Steam Sterilizers

These can help move around 25 liters and are suitable for smaller facilities with limited available space.

Moreover, these are also for facilities that do not need to sterilize as many medical tools each day.

Wrapping it Up

While buying a surgical tool sterilizer, you need to keep in mind the above categories, what they are made of, and whether they can be of use in the long term. Moreover, the ease of use, system and surgical tool size are all the factors that you should consider while getting a surgical tool sterilizer.

Comments