Surgical Handpiece Dental is one of the most important components of a dental setting for oral and maxillofacial surgery.

These handpieces are the most frequent uses devices in restorative dentistry.

However, there can also be a huge variation in quality, price, longevity, and after-sales support depending on the supplier brand and model of handpiece your choose.

Moreover, good-quality, well-maintained Surgical Handpiece Dental can help your practice minimize unnecessary expenditure.

Additionally, it can also help prevent delayed appointments at your office.

One of the important things to note is that the modern handpiece market offers a wide range of choices and prices.

While setting up a dental office you may consider both local and international brands to use in your office.

This guide aims to help you understand the types of Surgical Handpiece Dental, how they are used, and what to look for while buying them.

Choosing a Surgical Handpiece Dental

A handpiece is one of the most important and crucial components in your dental setting and for dental surgery.

For this very reason, many dentists like to make an informed decision when choosing the Surgical Handpiece Dental.

It is also of vital importance to make sure your choose quality, reliable, and high-performance surgical handpiece dental, for the efficient running of your practice.

Moreover, choosing a good-quality handpiece will increase productivity, reduce stress for patients, and even reduce running costs.

Additionally, when purchasing surgical handpiece mental, make sure you are buying a regulatory compliant product.

The internet is rife with counterfeit and even substandard non-compliant dental handpieces.

You may love to bargain, however, do not risk the safety of your patients or your registration on cheap sub-standard handpieces from a faceless company on the internet.

Investing in quality surgical handpiece dental will result in a return by providing years of service.

Also, make sure to consider the cost of your handpieces over a time period of about 3 to 5 years.

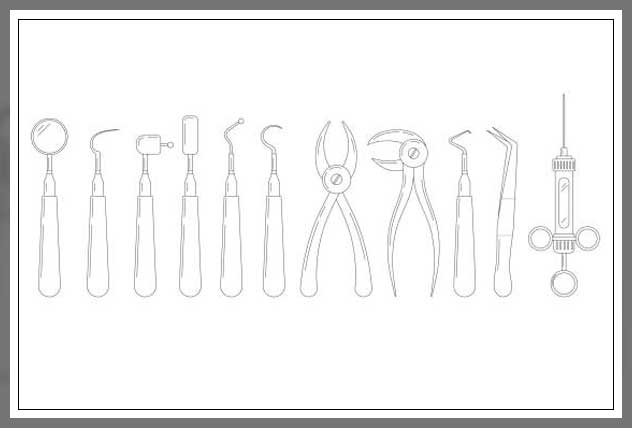

Learn more about Dentist Instruments: A Beginners Guide here.

Types of Surgical Handpiece Dental

There are two systems of powering Surgical Handpiece Dental: air turbine and electrical.

Air-driven handpieces contain an air-driven spinning turbine to generate rotation and are powered by compressed air.

Moreover, they can reach speeds of up to 400,000 rpm with variable torque.

On the other hand, electrical motor handpieces use an electric motor to drive the head.

And many consider them self-contained systems.

Internal gearings allow them to run at constant torque, i.e. consistent power with speeds of up to 200,000 rpm.

However, it is important to note that dental practices are increasingly using an electric motor.

These are quieter and often more cost-effective and can also be faster to use.

Types of Surgical Handpiece Dental are:

- high-speed handpieces

- slow speed handpieces

Learn more about Dental Laboratory Equipment List here.

High-Speed Handpieces

High-speed handpieces are often referred to as turbines that work in conjunction with a bur, a rotary cutting tool like a drill, and a drill bit.

These handpieces also rotate the bur/rotating cutting tool that speeds approximately between 200k rpm and 450 from.

Hence, this is how they get the name high-speed for maxillofacial surgery and implantology.

Moreover, a high-speed surgical straight handpieces dental is a precision medical device for the removal of tooth tissue efficiently.

It helps to prepare cavities for restorations and/or crowns and to section a tooth during surgery.

With the help of a correct surgical burs and cutters ø 2.35 mm, a good quality high-speed handpiece will help to cut through almost anything, 45 mm external spray maximum drive speed and speed 40,000.

Furthermore, a high-speed handpiece uses a burs and cutters ø with a 1.59 to 1.6 mm OD shank and mm also stryker system or 2.35 mm also stryker.

It is important to note that high-speed handpieces incorporate a cooling water spray to prevent overheating of the pulp.

This can occur due to the amount of heat otherwise produced from the high speed of the bur.

In some cases, you may find certain handpieces that deliver cooling spray via three spray ports that produce aerosols than other handpieces with four or more spray ports.

With various head sizes, high-speed handpieces drive entirely by air.

While smaller head size helps to improve visibility and access for useful posterior work and pediatric dentistry.

On the other hand, a larger head size produces more torque and helps in cutting power which speeds up the procedures.

Certain brands can even help achieve the optimal balance to deliver high performance, and low noise level at a size allowing good visibility and access for all procedures.

While some brands provide handpiece fittings suitable for all dental chairs.

Learn more about Dental Handpiece: Use, Types and Parts here.

Low-Speed Handpieces

In some cases, you may refer to low-speed handpieces as:

- contra-angles

- straight pieces

- attachments that generally use a 2.35 mm OD bur.

The examples include the high speed, the drill, and a drill bit.

It is important to note that low-speed handpieces are connected to and driven by a micro-motor which is air or electric driven.

You can determine the bur rotation speed of low-speed handpieces by motor driving.

A 1:1 ratio low-speed will rotate the bur at a maximum of 40K rpm when you attach them to an electric motor and approx. 20K rpm when you attach them to an air motor.

Moreover, you can use low-speed handpieces for the removal of soft decay, finishing cavity preparation, polishing, timing, and trophy work.

The different low-speed models, you can use for different functions are straight handpieces and straight can be dismantled for surgical procedures.

And also extraoral procedures like trimming dentures.

Furthermore, you can use some brands that provide low-speed contra handpieces for the removal of:

- decay

- to polish restorations

- refine cavity preparation

- adjust crown, bridges, and dentures

While some brands may also help for prophylaxis work when you want to trophy cup or bristle crush rotating slowly.

The 4:1 ratio means that it is 4:1 speeding reducing, rotation four times slower than the driving motor.

Additionally, contra-angle handpieces also supply a variety of speed ratios, speed reduction, and speed increases for the requirement of the procedure you perform.

Let’s discuss some of the important terms and parts for different surgical instruments and handpiece dental as follows:

Burs

Burs are the parts that drill into the teeth of the patients and are durable ergonomic and robust.

These are interchangeable, friction grip rotary instruments that are secured to the head of the handpiece.

These also use a lever chuck, push-button chuck, or conventional chuck.

The current standard is push-button systems that do not require a tool for changing the bur.

Moreover, there is a range of different burs of different sizes, shapes, and materials, and you can use them for different purposes.

Often, they are constructed from diamond, high quality stainless steel, or carbide.

Diamond burs tend to help high-speed handpieces to grind away harder surfaces like enamel. They also have a relatively short lifespan.

Tungsten carbide is a hard material that is much tougher than steel.

It cuts in the head making them long-lasting and effective as there is little debris buildup and stay also stays sharp for a longer time than steel.

Moreover, they are typically used to cut tooth structure rather than grind like diamond burns.

On other hand, steel burs are a low-cost solution that is softer and more flexible than tungsten carbide bars.

They tend to be blunt faster than carbide, however, are more resistant to breaking.

It is important to note that the tip of the bur can also be of a wide variety of shapes.

They can be either round burs or pear burs you can use for cavity preparation and creating access points and undercuts.

While cross-cut burs have cuts in the blade to prevent debris buildup and help for sectioning and shaping teeth.

You can use finishing burs for finishing restorations and shaping soft tissues.

Two numbering systems help to identify burs: the ISO system labels burs with a 15-digit code.

It helps to identify the bur type, shank type, length, head shape, grit, i.e. coarse versus fine, and maximum head diameter.

Connectors

Connectors or couplers attach the handpiece to the dental unit tubing to deliver water and air to the handpieces.

One of the most common connections is Borden, i.e. two holes, and Midwest, i.e. four holes.

A Bordon Connection has one large hole to provide air that allows the turbine to spin and a smaller hole for cooling water.

On the other hand, the Midwest fitting has two large air holes to allow air in and out, i.e. exhaust.

It also contains a cooling water hole and a chip air hole.

Moreover, a chip air hole directs air onto the cutting surface to help cool the tooth, disperse the water spray, and clear debris.

It is also possible to convert between two-hole and four-hole connectors.

Many manufacturers have their own uniquely designed couplers.

Therefore, it is important to make sure you are purchasing a handpiece with the right fitting.

Learn more about Dental Digital Radiography: A complete Guide guide.

Other Important Parts

Some other important parts are:

Light

While you may be using external lights, many handpieces today come with integrated lights.

These help to provide light intraorally.

Often, halogen or mini LED lights are used. You may prefer LED lights due to their longer working life, more intense light, and lower heat production.

Noise

A noisy handpiece can be off-putting to your patients. Air handpieces tend to be much older than electric handpieces due to the sound of compressed air.

However, electric handpieces generate less vibration than air turbines.

Materials

Manufacturers often differentiate their products through superior and high-quality materials.

Make sure to look for ceramic bearings, i.e. hard-wearing, titanium bodies, that are stronger and more durable, and a special ‘smart’ coating for increased grip.

Specialist Handpieces

These are available for endodontic and surgical procedures.

Learn more about What is The Role of a Dental Lab? here.

Surgical Handpiece Dental Care and Lubrication

One of the most important things to understand is that you need to take care of your Surgical Handpiece Dental and a wide range of maintenance and sterilization equipment is available to help you with that.

Moreover, you can also get specialists lubricating system with a built-in filter. Another thing to note is that all handpeices need lubricating with handpieces oil to keep them working smoothly and efficnelty

Many brands provides trouble-free, effiecnt dental handpiece repair services with credited technicians and parts. They also provide warranty repairs and postage when you frequent any repairs.